When I built my custom cabbing machine I bought a set of Diamond Pacific wheels. The set designed for a Titan (8" wheels). The set consists of two galaxy (hard) wheel in grits 80 and 220 and four Nova (soft) wheels in 280, 600, 1200 and 3000.

My machine has always worked well and I love the wheels, but I noticed a problem with my 220 galaxy wheel early on. I thought it would work itself out but instead the problem seems to be getting worse as the wheel breaks in. The problem lies in the fact that somewhere on the 220 wheel there is (what I am assuming is) a bit of contamination that was introduced during manufacture. Whatever it is it creates scratches that are deep enough that they do not come out as I continue on through the grits. I can actually grind out these scratches on the first nova wheel (280) but only if I have identified where they are and have left enough meat in the stone to work them out. And the problem is they are very hard to see until you get into the polishing stages. When the stone is wet they cannot be seen at all and when the stone dries out I usually cant see them until at least after the 600, and thats only on stones that already start to take a shine at that grit.

I have taken to jumping from shaping on the 80 grit to going directly to 280, especially on things like obsidian where these scratches are devastating to the finish. I have to assume the offender is a small diamond particle embedded in the 220 wheel because it is hard enough to scratch even the hardest things I have ever cut. I thought maybe it would pop out or wear off, but it seems to be getting worse as the wheel wears in. I don't cut lots of rock so I expect my wheels to last for years. In fact I've already been using them for a couple years and they are just getting broke in nicely, but I can't continue with this one. I have tried inspecting the wheel meticulously under magnification but I cannot identify the spot.

The scratches are small so I know the contamination is small. In hand on most stones where I still have scratches after finishing them it is very hard to see the scratches with the naked eye. The exception is darker stones in uniform colors with a high gloss finish. Things like bruneau and obsidian are terrible unless I can find the scratches at the next stage and remove them. Lots of my finished stones I haven't even noticed the scratches until they were done and I started trying to take macro photos of them. Then I'm like "Awww Damnit!!"

So has anyone ever had a problem with a wheel like this in the past? Is there a way I could identify the offending spot and possibly remove it? Do I need to bite the bullet and just buy another wheel? Any help or suggestions would be appreciated.

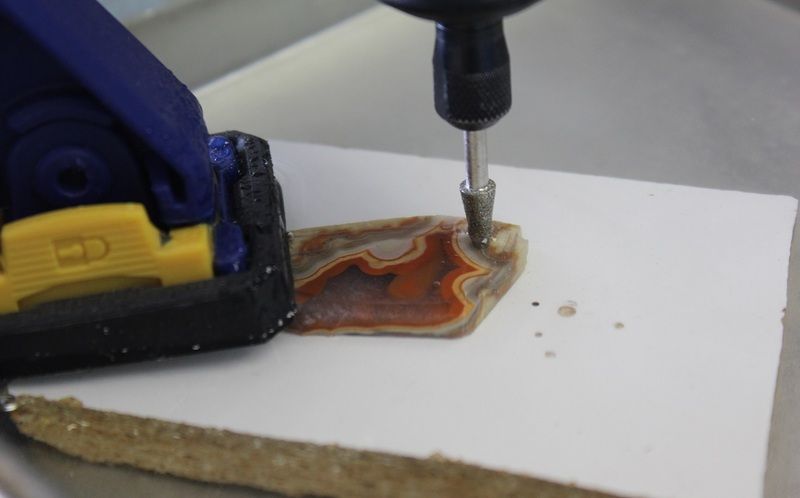

Here is a stone I finished today to illustrate. This is a piece of agua nueva agate. The cab is large (about 56X43mm) so the dome is fairly low. In hand the scratches are all but invisible. You have to look at a reflected light source shining off the stone where the scratches are to see them with the naked eye. But in the photos I took they are very apparent and it drives me crazy. You see them as the small white streaks crisscrossing the center of the stone.